Initiatives for sustainability

Made in Japan

All Lagimusim products are made in Japan.

The paanibag fabric is made in the Tohoku region.

Cutting and sewing are made at a factory in Yamanashi Prefecture.

Commitment ①

Thorough efforts to reduce waste in the production process.

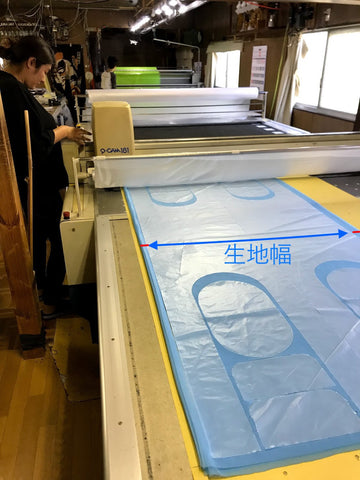

By keeping in mind the "width of the fabric" when considering the dimensions of the product, we are devising ways to prevent waste.

For example, by dividing the width of the 180 cm fabric into quarters, there is almost no excess fabric for the width. (The parts marked in red are the parts that become garbage, such as the edge of the fabric and the folded part of the fabric.)

With this in mind, the factory judges if there is a gap in the fabric when cutting, and devise it so that there is no waste.

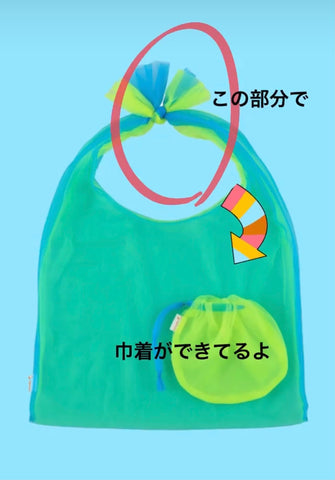

In addition, the fabric that is left over from the handle part of the bag is used as a drawstring or pouch, or as a string used for flags and drawstrings, etc., so that there is no waste fabric.

Commitment ②

Don't make too much. balanced production.

We attach great importance to communication with the factory. By telling you how much inventory you have, the sales situation, and the outlook for this year, you can prevent overproduction and prevent the factory production system from being overloaded. I am taking

Lagimusim feels that the factory sees Lagimusim as their own by conveying the feeling of "wanting to have a long-term relationship". Based on the premise of a long-term relationship, the factory works with us to create good products at well-balanced prices with a long-term perspective, and takes pride in quality.

Commitment ③

Zero waste.

In overseas factories, labor costs are low and the working environment is poor. In addition, there is a problem of mass production through thorough streamlining and mass disposal of surplus inventory.

Lagimusim does balance production, so there is no inventory to discard.

Lagimusim does not adopt the common sense of apparel [production for each season, sale of unsold items, and disposal of any leftovers].

Good things that will be loved for a long time.

Unlike food, it doesn't spoil, but it still retains its freshness. When we are conscious of freshness, we tend to think of new things all the time.

I am conscious of taking time to get to know each product and to convey it firmly.

Commitment ④

Japanese quality.

For example, the paanibag is reversible, but the factory suggested sewing the corners together. They are always looking for better suggestions to make it easy to reversible and look good (despite the fact that their own process will increase).

Only 2.0% of the clothes distributed in Japan in 2019 were made in Japan. I have heard many difficult stories, such as the experience of a client switching to overseas production, or the factory of a colleague going out of business. I'm here.

The quality is directly reflected in the consciousness of those who actually move their hands. Lagimusim has many fabrics that are difficult to sew, so I think it's a product that reflects that.

Discerning ⑤

price disclosure.

The price is disclosed on each product page. We believe that customers have the right to know the manufacturing cost.

I will tell you in more detail here. In the case of paanibag regular size, the cost (¥870) shown in the figure is sold for ¥2500. ¥1630 is not a profit, and the following charges are applied at the WEBshop from there.

- If customer shipping is free (¥370 or ¥700 or more)

- Fee (e.g. credit card settlement fee 3.4%)

- Warehouse (storage fee and work fee for warehousing and shipping)

- Photo shoot/DM etc.

The following charges apply when handling in-store.

- Estimated store fee 40% (¥1,000)

- Postage to stores/POP creation/Sales, etc.

Anything else,

- Site operating costs/construction costs/inquiries, etc.

- Product design and web design

- SNS management

- Various management/accounting etc.

Discerning ⑥

Challenge to zero waste.

In (1), we talked about how we are trying to reduce waste in the production process, but there are still some fabrics that become waste. For example, fabric ears (edges of fabric). We will consider how to use the waste materials that are generated in the manufacturing process and aim for zero. In addition, we will face the current situation where products after use become waste and make improvements, and in 2021, we will take on the challenge of zero waste.

As one of our efforts, we are working on creating a system to provide waste materials to those who utilize them. (Photo: Reborn as a new product by Kankichi Koubou .)